“Your Fluid Handling Experts”

Industrial Distributor & Supplier of Progressive Cavity Pumps

Fischer Process Industries carries, supplies and distributes progressive cavity pumps manufactured by SEEPEX, an industry leader and most recognized name in progressive cavity pumps. A progressive cavity pump is a type of positive displacement pump that is typically used when the pumping application is not suited to a centrifugal pump. Progressive cavity pumps are well suited for liquids with higher viscosities.

SEEPEX Progressive Cavity Pumps

We are an authorized dealer of SEEPEX Progressive Cavity Pumps in Central/Eastern Kentucky and Southern West Virginia regions. Below are several examples of some of the SEEPEX products we supply and distribute. Please contact us for more information or to request a quote.

N STANDARD PROGRESSIVE CAVITY PUMPS

The N range is the robust basis for all SEEPEX progressive cavity pumps. It can pump low-viscosity to viscous media, with and without solids, and can be used in virtually all industries.

T OPEN HOPPER PUMPS

SEEPEX open hopper pumps are used to discharge thickened and dewatered sludges for onward processing. SEEPEX can also directly mount pumps under storage silos that have a capacity to backmix to control sludge dry solids content.

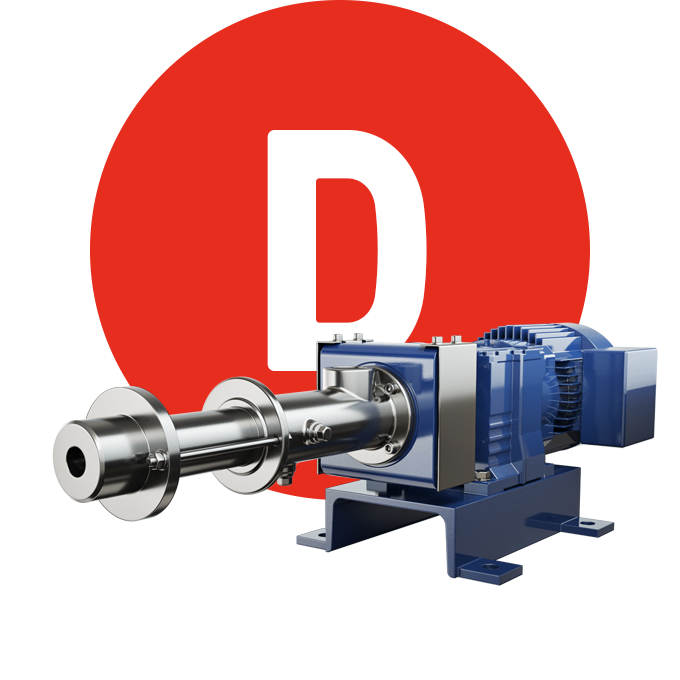

D METERING PUMPS

Metering pumps are used in the environmental and mining industries to accurately dose various chemical and polymer solutions that are used for both improving water quality and improving dewaterability.

CS FOOD & HYGIENIC PUMPS

In areas with sensitive hygienic requirements, cleanliness is a critical factor. SEEPEX food and hygienic pumps fulfill even the strictest hygiene requirements in the food, pharmaceutical, cosmetics and chemical industries.